Laser Cutting Method

Laser cutting offers precision and flexibility across various sectors, from oil and gas to renewable energy. Here’s how our state-of-the-art technology meets the demands of diverse industries.

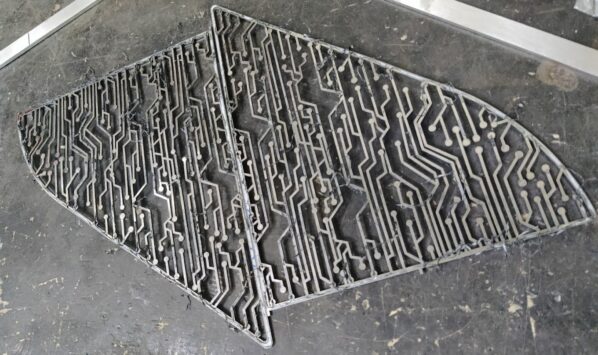

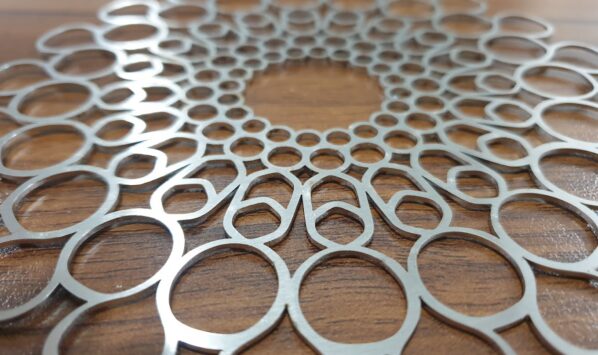

1. High-Precision Cutting

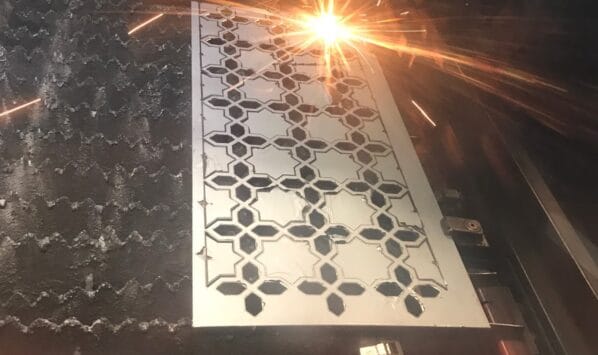

- Laser cutting is a highly accurate technique that utilizes a focused laser beam to cut through various materials, ensuring precise and clean edges in metal, wood, acrylic, and more.

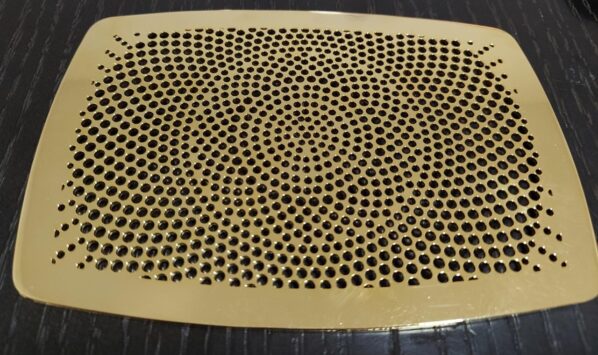

2. Versatile Material Compatibility

- Our state-of-the-art laser cutting technology is adaptable to a wide range of materials, including metal, wood, and acrylic, meeting diverse industrial needs.

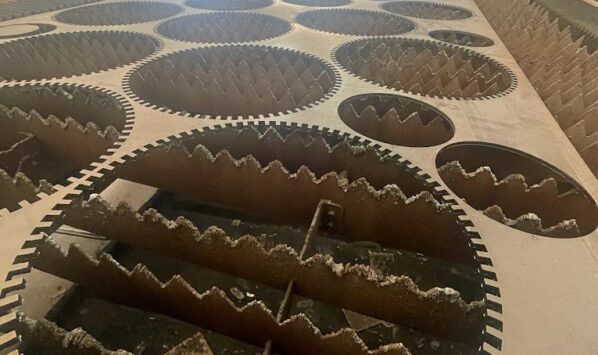

3. Customizable Solutions

- Ideal for complex shapes, intricate designs, and tight tolerances, laser cutting enables customizable solutions tailored to specific project requirements.

4. Industries Served

- Oil and Gas: We provide custom metal components for oil rigs, refineries, and pipelines, delivering the durability and precision essential to the industry.

- Telecommunications: Our laser-cut parts are used in housing, brackets, and assemblies for telecom infrastructure, supporting high-performance requirements.

- Manufacturing: From metal prototypes to production-ready parts, we support the manufacturing industry with reliable, repeatable, and fast production capabilities.

- Prototyping: Laser cutting is ideal for prototyping, allowing rapid iteration and modifications to meet specific project demands.

- Healthcare: Precision components for medical devices and equipment, ensuring strict adherence to industry standards.

- Aerospace and Maritime: We produce high-precision metal and composite parts essential for the aerospace and maritime industries, where quality and accuracy are paramount.

- Renewable Energy: Our laser-cut components support the renewable energy sector, from wind turbine parts to solar panel mounts.

5. Efficient Production Process

- Laser cutting reduces waste, improves efficiency, and speeds up production timelines, ensuring cost-effectiveness for all industries.

6. Environmentally Friendly

- Laser cutting generates less waste and is more energy-efficient, aligning with sustainable practices essential to today’s industries.

Laser cutting generates less waste and is more energy-efficient, aligning with sustainable practices essential to today’s industries.