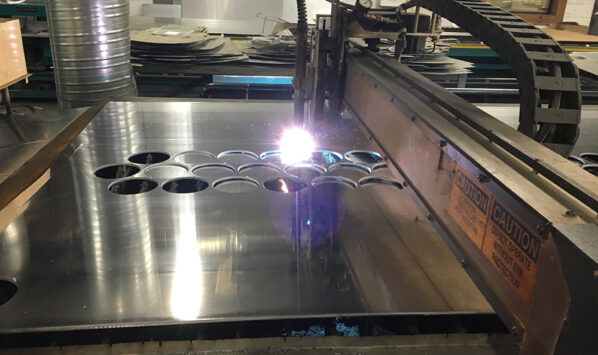

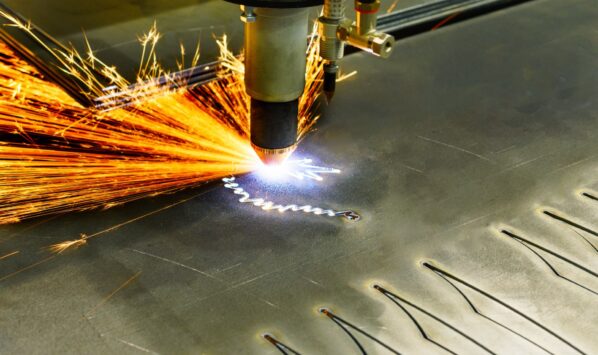

Plasma Cutting Method

Plasma cutting is a versatile and efficient cutting process suitable for heavy steel materials ranging from 2 mm to 100 mm thick. Utilizing a high-velocity jet of ionized gas, plasma cutting provides precise cuts with minimal heat distortion, making it ideal for various industries.

Key Features

- Thickness Range: Effectively cuts steel materials from 2 mm to 100 mm thick.

- Precision Cutting: Produces clean, accurate cuts with tight tolerances.

- Minimal Distortion: Reduces heat-affected zones, preserving the integrity of the material.

- Speed: Fast cutting speeds increase productivity and efficiency.

Advantages

- Cost-Effective: Reduced labor and material waste compared to traditional cutting methods.

- Versatile Applications: Suitable for various shapes and designs, including intricate details.

- Adaptability: Can cut through a variety of metals, including aluminum, stainless steel, and carbon steel.

Industries Served

- Oil and Gas:

- Fabrication of pipelines, tanks, and structural components.

- Maintenance and repair services for offshore and onshore facilities.

- Pre-Engineered Buildings:

- Production of steel frames and components for quick assembly.

- Custom cutting solutions for unique building designs.

- Telecommunications:

- Manufacturing of towers and support structures.

- Cutting of cable trays and enclosures.

- Manufacturing:

- Creation of parts and components for machinery and equipment.

- High-volume production capabilities for industrial applications.

- Aerospace:

- Precision cutting for aircraft components and structures.

- Adherence to strict industry standards for quality and safety.

- Maritime:

- Construction and repair of ships, boats, and marine equipment.

- Custom solutions for various marine applications.

- Renewable Energy:

- Fabrication of components for wind turbines, solar panels, and other renewable systems.

- Support for sustainable energy initiatives through efficient metalworking.

- Other Relevant Industries:

- Heavy equipment manufacturing, automotive, and construction sectors.

- Custom fabrication services for specialized projects.