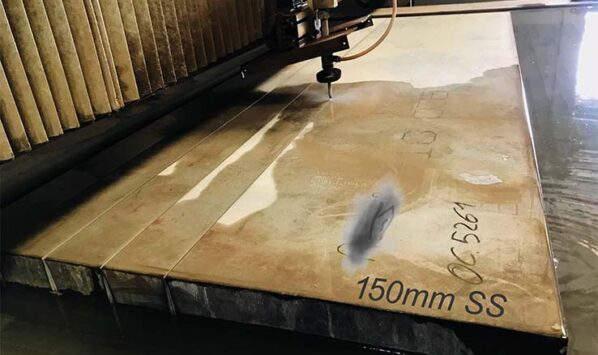

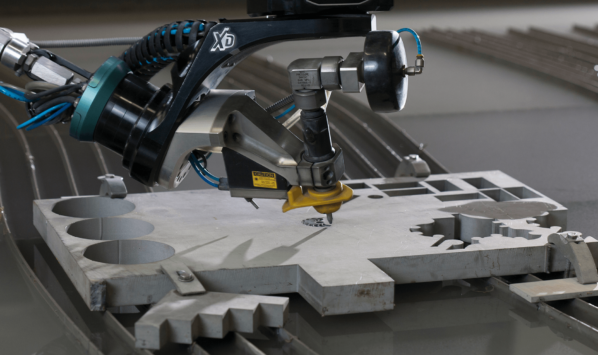

Water Jet Cutting Method

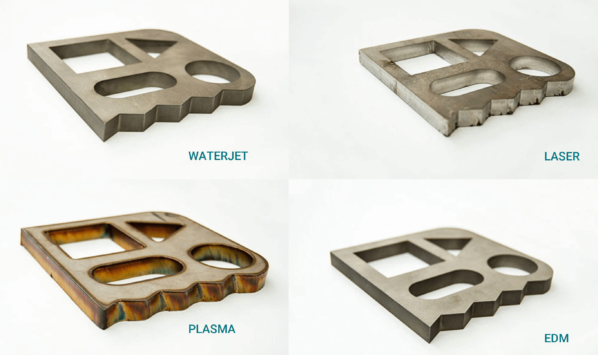

Water jet cutting is a versatile and environmentally friendly cutting method that uses a high-pressure jet of water or a combination of water and abrasives to cut through materials without generating heat. This process is highly effective for materials sensitive to heat and maintains a clean, smooth cut on various surfaces.

Key Features

- Cold Cutting Process: Water jet cutting generates no heat, preserving material properties and reducing the risk of warping or distortion.

- Precise Cutting: Achieves high accuracy, making it ideal for intricate shapes and tight tolerances.

- Environmentally Friendly: Uses only water or natural abrasives, making it a sustainable option with minimal waste.

Advantages

- Versatile Material Compatibility: Suitable for metals, plastics, glass, ceramics, and composite materials.

- Clean Finish: Produces a smooth edge without the need for secondary finishing.

- No Heat-Affected Zone: Maintains the integrity of heat-sensitive materials, as no heat is involved.

Industries Served

- Aerospace

- Precision cutting for metals and composites used in aircraft and spacecraft components.

- Maintains structural integrity of materials essential in aerospace engineering.

- Automotive

- Production of parts and components requiring high precision and tight tolerances.

- Used for both prototyping and manufacturing of automotive parts.

- Architecture and Construction

- Cutting of materials like stone, glass, and metal for architectural designs and structures.

- Allows for complex designs in building materials without compromising quality.

- Electronics

- Ideal for sensitive electronic components that may be damaged by heat from other cutting methods.

- Used for cutting circuit boards, insulation, and other delicate components.

- Manufacturing

- High-precision cutting for various materials in industrial manufacturing.

- Provides a cost-effective solution for bulk material cutting and customization.

Benefits of Water Jet Cutting

- Flexible Cutting Capabilities: Cuts a wide range of thicknesses, from thin sheets to thick materials up to several inches.

- Reduced Waste: Cuts with precision, reducing material wastage and cost.

- Eco-Friendly: Minimizes environmental impact by using water and natural abrasives without toxic fumes.

Our water jet cutting services meet the stringent demands of industries ranging from aerospace to electronics, ensuring a clean, accurate cut and preserving material quality for every project.